Finishes

Below is information on all of our concrete finishes:

The colour of the cement defines the colour of the precast concrete element.

(EXPOSED AGGREGATE)

After the panel is stripped from the mold, cement and sand are removed from the concrete surface by power washing. This is possible because the hardening of the concrete surface is delayed by use of chemical retarder. The size and colour of the exposed coarse aggregate provides the texture and colour of the precast panel.

(EXPOSED AGGREGATE)

Sandblasting removes the cement sand matrix by abrasion. A varying degree of sandblasting (light, medium and heavy) provide different visual effects to the panel surface. As the sandblasting depth increases, more of the coarse aggregates are exposed.

Double-Click image to view full-size.

(EXPOSED AGGREGATE)

Acid applied to the concrete surface dissolves the surface cement paste to reveal the sand and some coarse aggregate. Acid etching produces a fine sand texture that resembles the look of natural limestone.

Double-click image to view full-size.

(EXPOSED AGGREGATE)

A rough surface texture is achieved by use of mechanical tools to spall or chip and remove a layer of the hardened concrete surface. The resulting finish has a distinctive character.

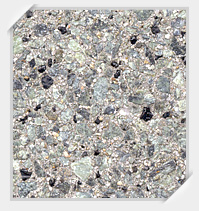

Polished and honed finish is created by grinding the concrete surface several times with grinding tools varting from coarse grit to a fine grit, using a finer grit each time.

Air voids in the concrete surface are filled before each of the first few grinding operations by using a sand-cement mixture that matches the matrix of the concrete.

In addition to the series of grindings for smooth matte honed finish, to achieve high gloss polish, final procedure is to use buffer brick or felt pad with tin oxide polishing powder on the concrete surface.

Double-click image to view full-size.